Month: May 2016

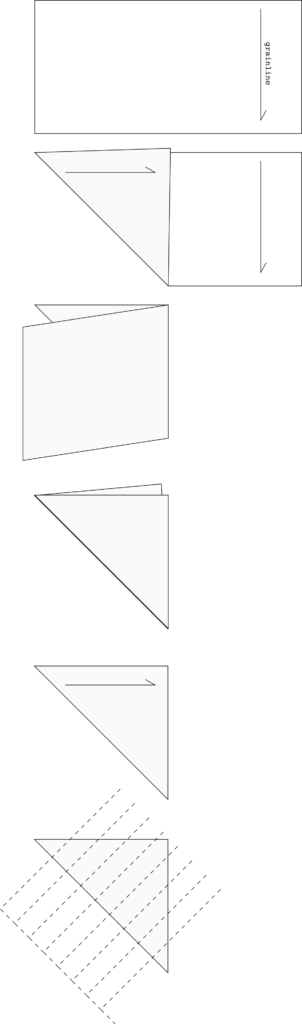

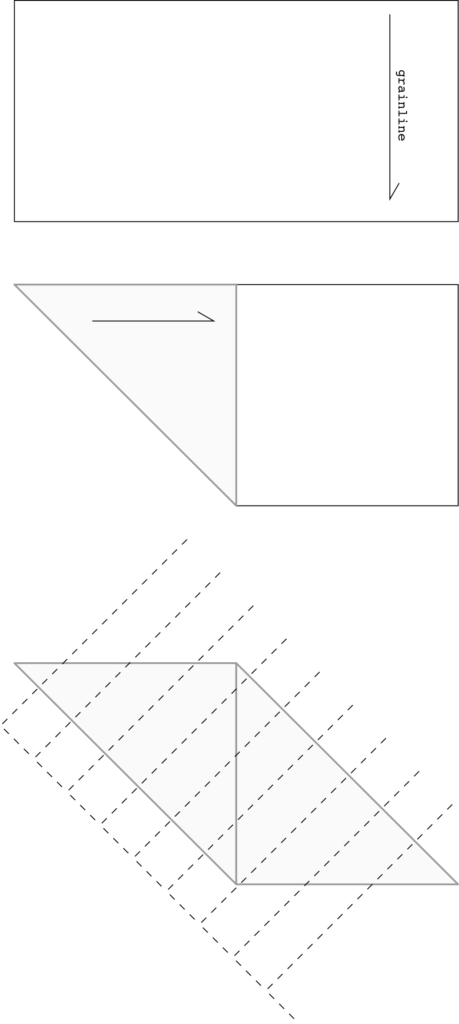

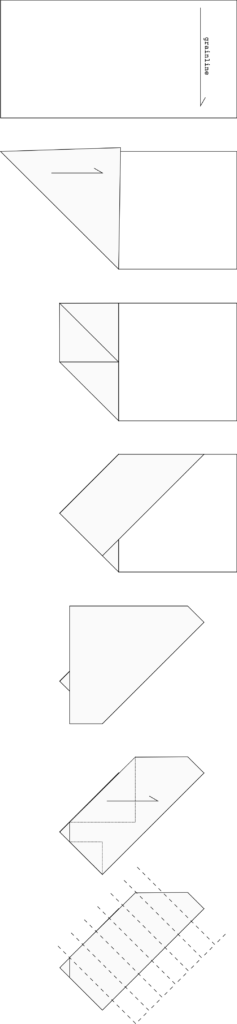

Cutting Folded Bias

To help with cutting long bias tapes, fold the fabric over to shorten cutting distances:

Or:

Or:

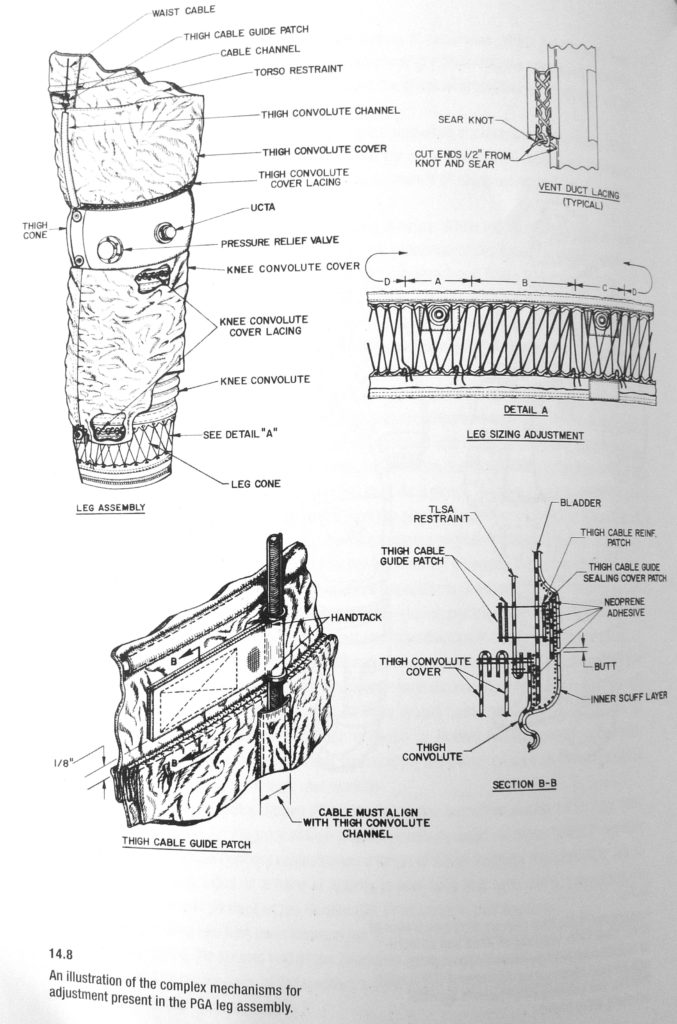

Space Suits Still Made the Old Fashion Way

Taken from “Spacesuits: Fashioning Apollo” by Nicholas de Monchaux:

“Yet here is a deep irony—a central, incongruous fact of Apollo’s history. For all the management efforts spent acclimatizing ILC to NASA’s military-industrial milieu, the most heavily reproduced Apollo artifact—the A7L spacesuit seen on stamps, in statuettes, and on screen in its essence a throwback, a regression, the sole exception to a rule. For, even as ILC’s most dedicated managers would later admit, the forest of paperwork thrown around the suit’s craftsmanship was, essentially, ‘a bit of a smokescreen,’ hiding a hand-crafted nature. Whether in the ‘dipping’ of convolutes, the glueing of layers, or the sewing of the final suit, ILC’s process was so dependent on the individual craftsmanship of its employees that attempts to enumerate precisely the procedures used were inherently impossible. As a seamstress later reflected, ‘no two people sew alike.’ While the change of even a sixteenth of an inch in a formalized sewing procedure needed to be debated and recorded in a systems engineering ‘configuration board,’ the procedures recorded in paperwork were never precisely those used to assemble the suits. NASA’s consistent delight with ILC’s suits, and constant frustration with the firm’s paperwork, were not contradictory. In fact, they were of a piece. As the many counterexamples to ILC’s expertise show, any attempt to fit the human body precisely into the procedures of systems management seemed destined for difficulty. ILC’s mastery of the body, and the tucking, tweaking, and tailoring needed for its comfort, placed it inherently at odds with the rest of Apollo’s organizational framework. Its success in negotiating that framework—just enough to secure and maintain the suit contract into the 1970s was, as we have seen, itself a marvel of layered adaptation.”

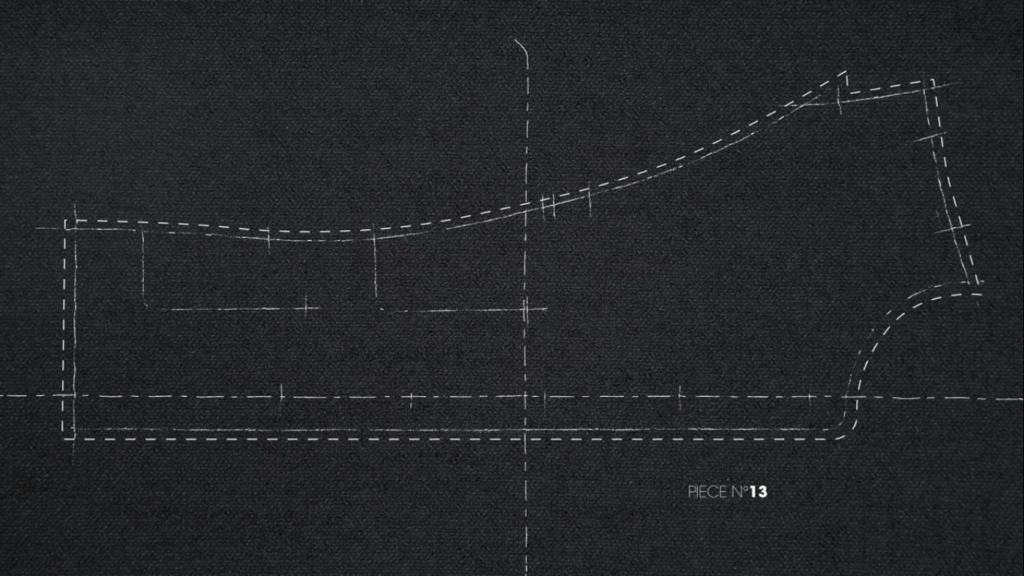

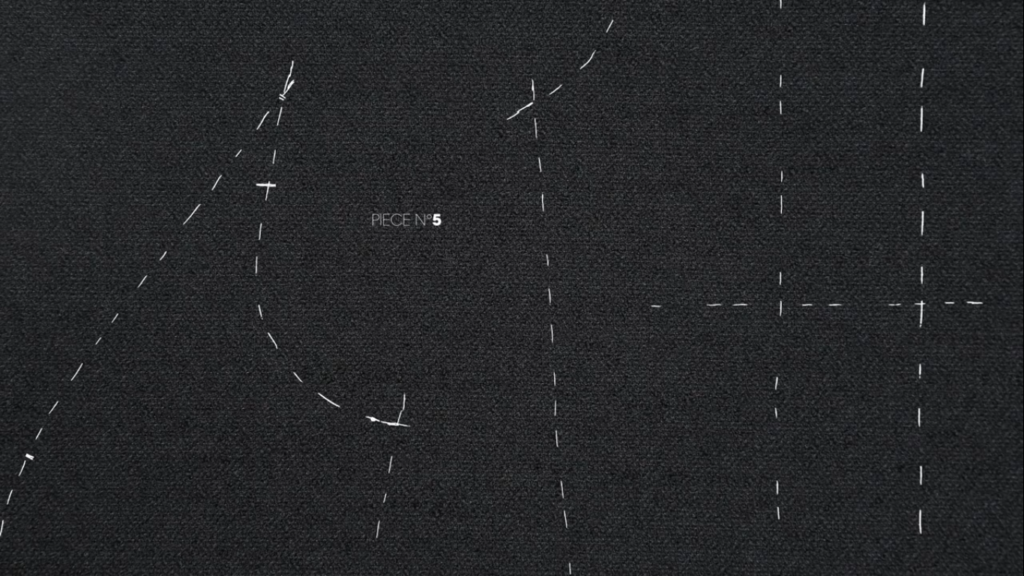

Women’s Jacket Design & Development Notes

Silhouette interpretation.

Take 30 measurements on body.

Using a Stockman mannequin to start muslin mockup.

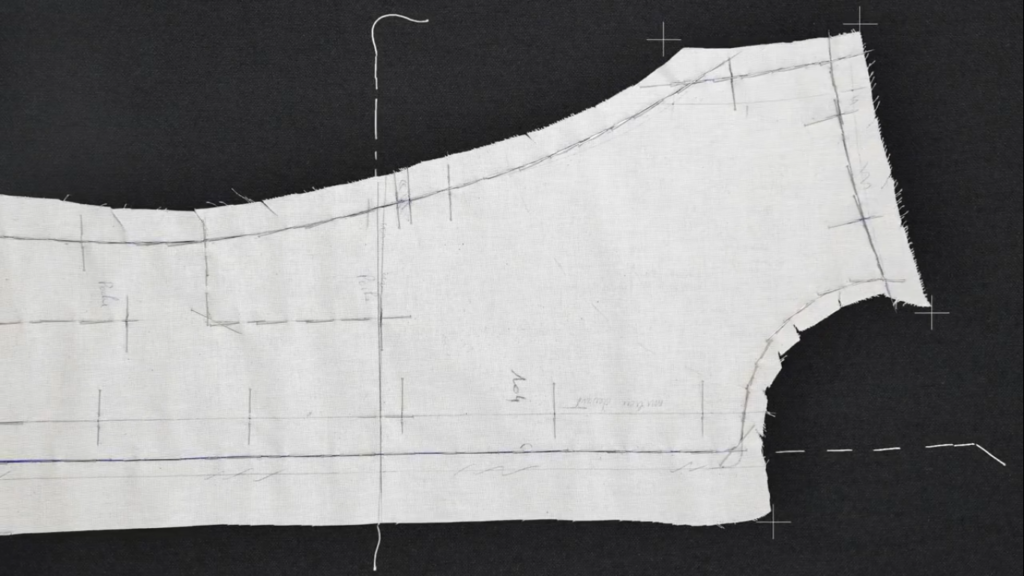

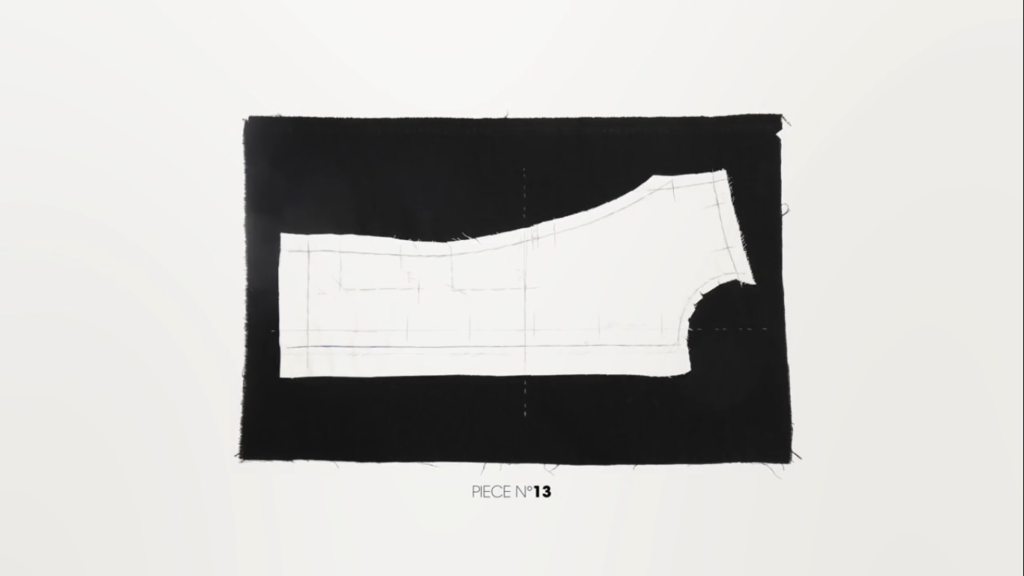

Pattern & muslin addjustments.

Higher waistline for closer fit.

Rounder back for proportion.

Cut sleeves higher to “liberate the movement”—possibly they mean to cut a lower cap height. This might be achieved by transferring the tighter shaping with the split seam running down the outside of the sleeve. (It is also possible that this might be a three part sleeve: undersleeve, back upper sleeve, front upper sleeve)

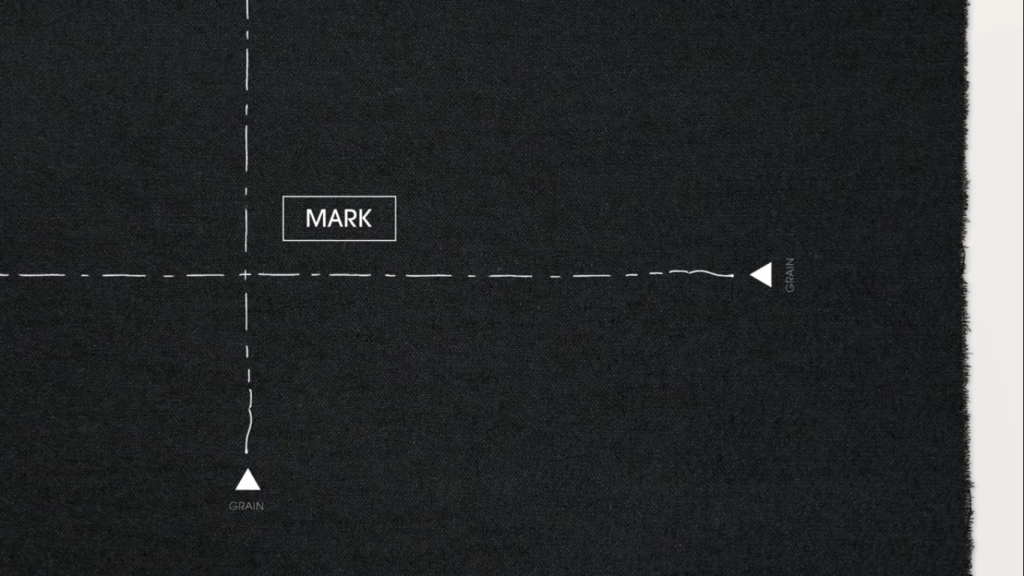

Mark final fabric with straightline grain basting stitches.

Pin muslin pattern to final fabric on grainline.

Outline with chalk / wax.

Baste thread around chalk / wax lines.

Assemble and baste for final fitting.

Add trim, buttonholes, and buttons.

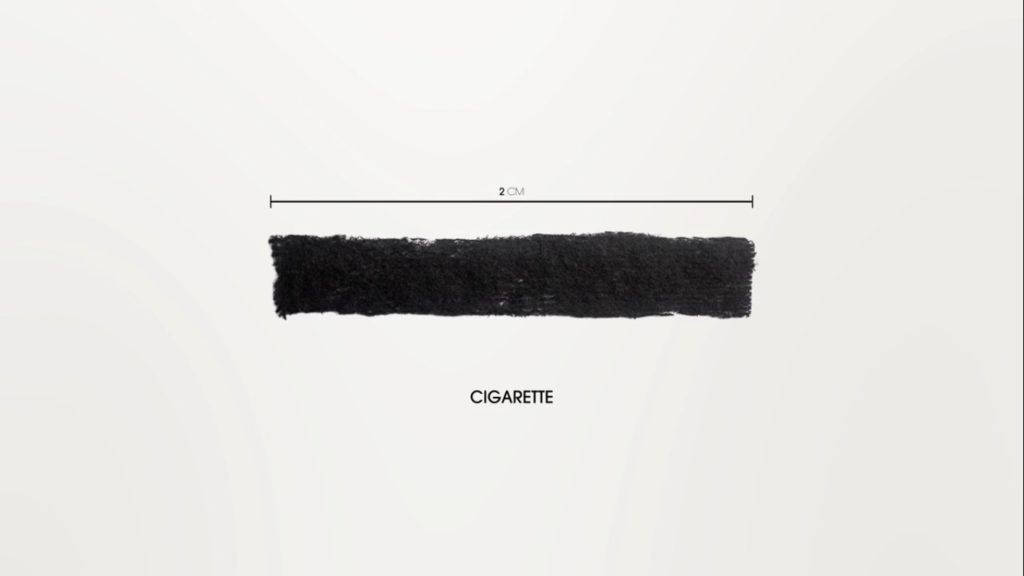

A “cigarette” for sleeve head shaping.

Apply chain weight.

Front & Back:

Finished Product:

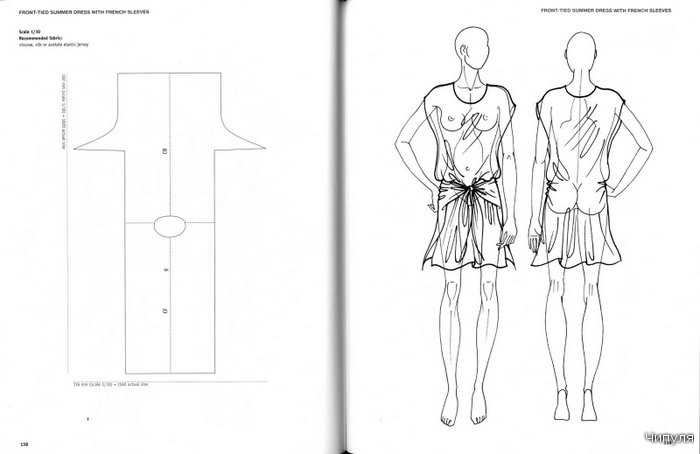

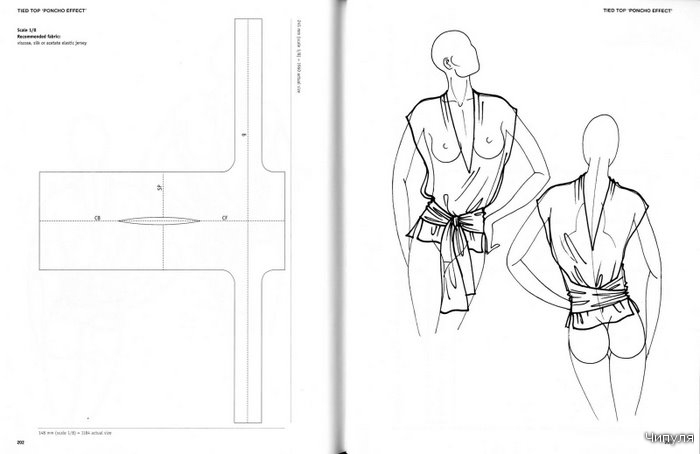

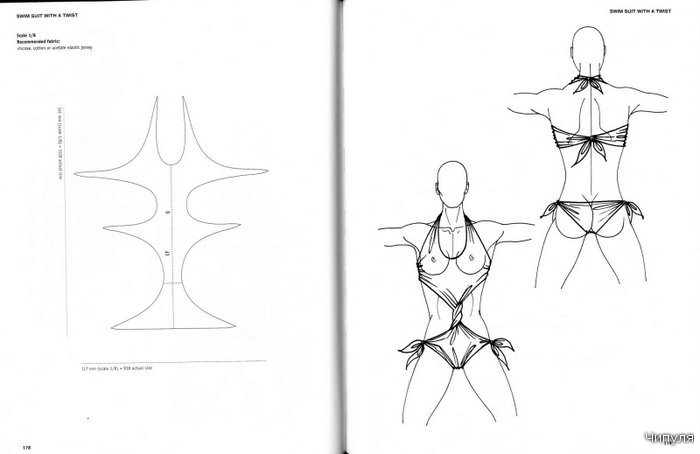

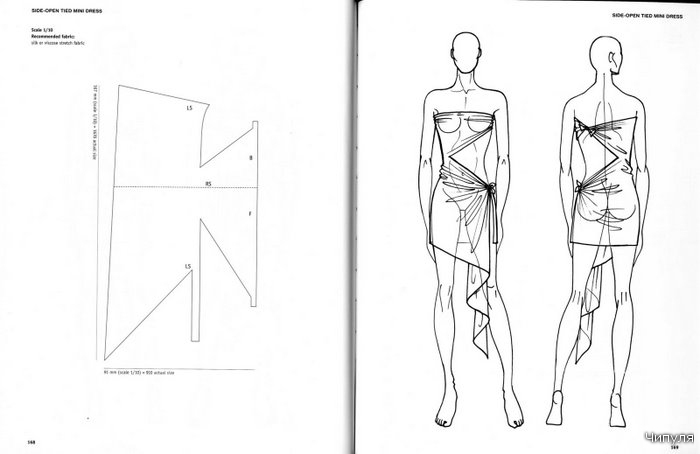

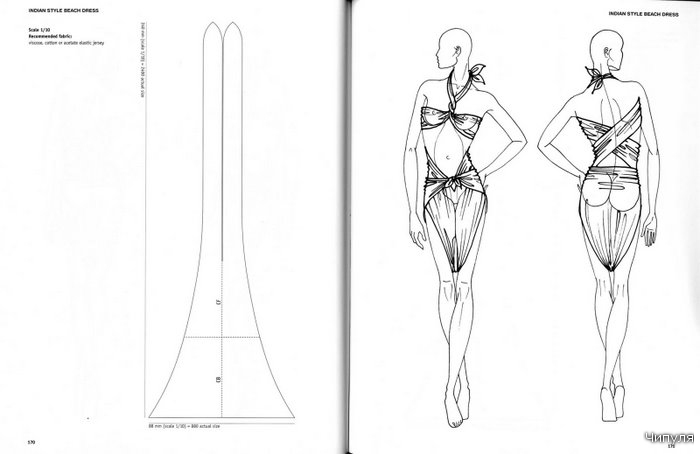

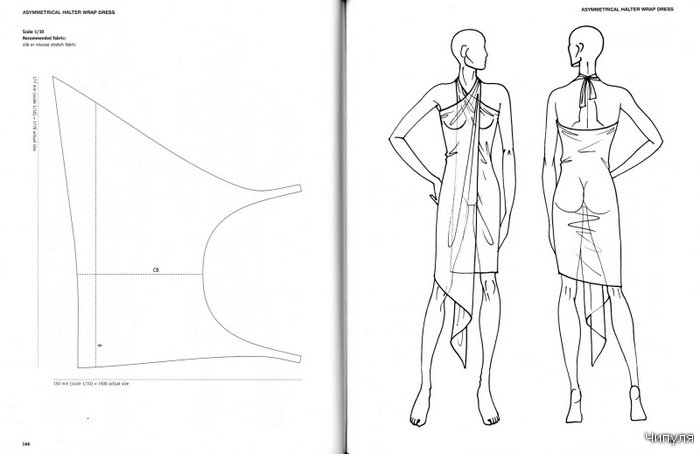

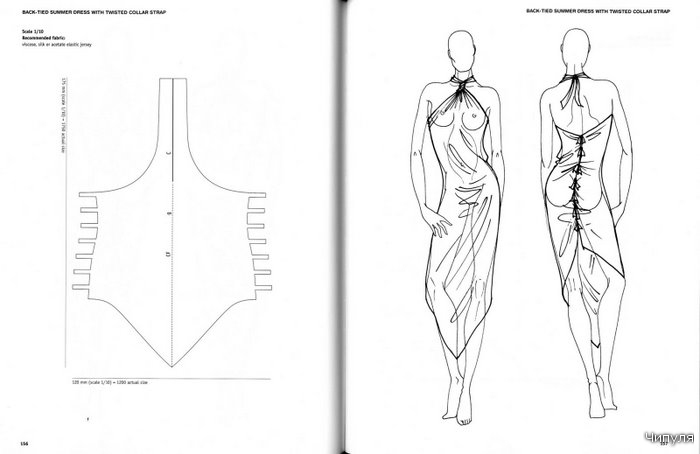

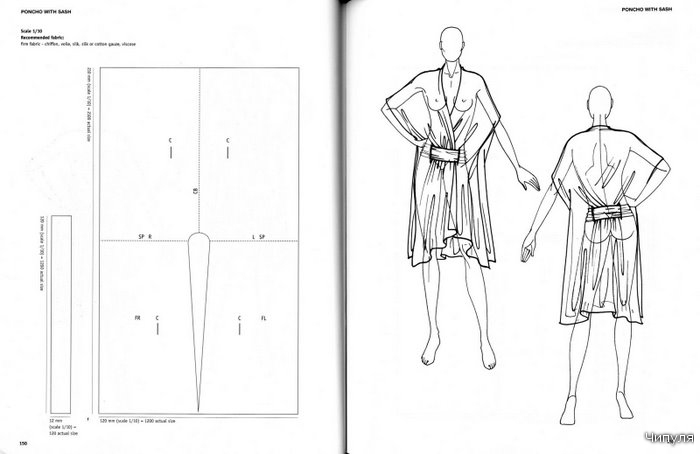

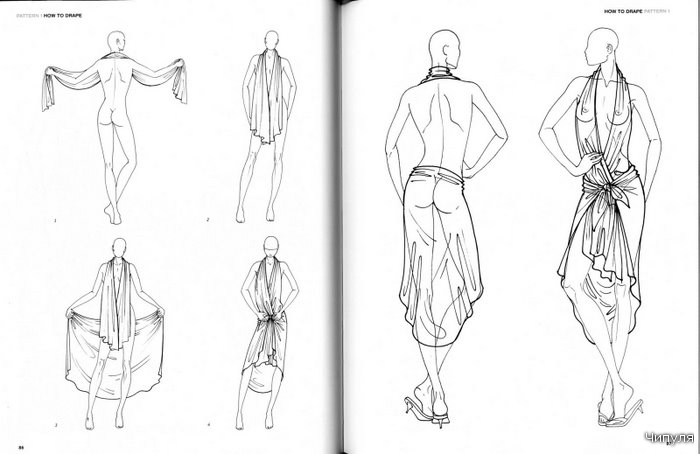

Wrap Dress Ideas & Patterns

From Wrap & Drape Fashion